About Us

Founded in 1985, Clad Metal Specialties is a a full-service metal processing firm that produces high-quality metal cladding according to customer specifications. Since our inception, we’ve offered custom Full Clads, Inlays, and Toplays to Stampers and OEMs in the Aerospace, Appliance, Automotive, Computer, Electronics, Medical, Military, Scanning and Mobility, and Telecommunications industries.

In May 2025, Prince & Izant Company, a leading manufacturer of highly engineered brazing alloys and precious metals for critical and demanding applications, acquired Clad Metal Specialties.

The management team at Clad Metal comprises individuals with over 60 years of combined professional experience in the industry. Our management team, along with our dedicated staff, currently operates our 12,500 sq. ft. facility located at 1516 Fifth Industrial Ct., Bayshore New York.

Our product line includes single and double overlay clads, toplays, inlays, and contact materials. We maintain a full line of non-ferrous metals in various thicknesses, widths, and tempers for fast turnaround, short-run, or prototype projects.

Additionally, we offer in-house rolling, slitting, and annealing equipment to assist our customers in converting excess inventory into usable products, thus maximizing profits.

Clad Metal Specialties promptly attends to your needs with personal attention. Our staff possesses the training and experience required to take your project from prototype through production. We prepare quotes quickly to meet your deadlines, often returning them the same day. We meticulously document and monitor the progress of your order from the moment it’s entered. To ensure quality and on-time delivery, we use the latest technology to record customer specifications, requirements, and all in-process inspection measurements and testing.

Our bonding and rolling mills have undergone updates with Vollmer equipment, including operator interface intelligence systems with automatic screw-downs and SPC measurement systems that chart real-time data with printouts.

Our Affiliates

- American Society For Testing and Materials

- ADDAPT- The Aerospace & Defense Diversification Alliance In Peacetime Transition, Inc.

- Fabricators & Manufacturers Association, International

- ASM International

- The Business Council of New York State, Inc.

- Chamber of Commerce Association

- PMA

Quality Control

Clad Metal Specialties has established a customer oriented quality management system to put its commitment to quality into practice in both its long term and daily activities. We continuously strive to produce and provide quality products and services which meet our customer requirements. This quality policy statement above is known by all our employees and is intended to show our commitment to our customers. The Quality Management System and its associated procedures, work instructions and related documents establish Clad Metal Specialties objectives for quality performance throughout its operation and are designed to be consistent with ISO9001/AS9100 standards.

Management is committed to ensuring that these policies are understood and implemented throughout the organization.

- ISO 9001

- AS9100

- ITAR – International Traffic in Arms Regulations

- FCR – Federal Contract Registry

- NAFTA – North American Free Trade Agreement

- Conflict Minerals Statement

- Environmental Safety Statement

- RoHS Directives Statement

Benefits of Clad Metal

Roll-bonded strips make it possible to use specialty metal economically in the thickness and width necessary for contact. Roll-bonded strips allow extensive freedom in the selection of the contact and base metal.

The contact metal can be selected according to aspects such as resistance to influences from the ambient atmosphere or abrasion resistance in the case of friction contact, and to select the base metal according to electrical conductivity, strength, spring bending strength or corrosion resistance. Good bending flexibility in the contact area. They have low inner stresses as compared with galvanic coatings. With this mode of manufacture, an optimum material structure is possible.

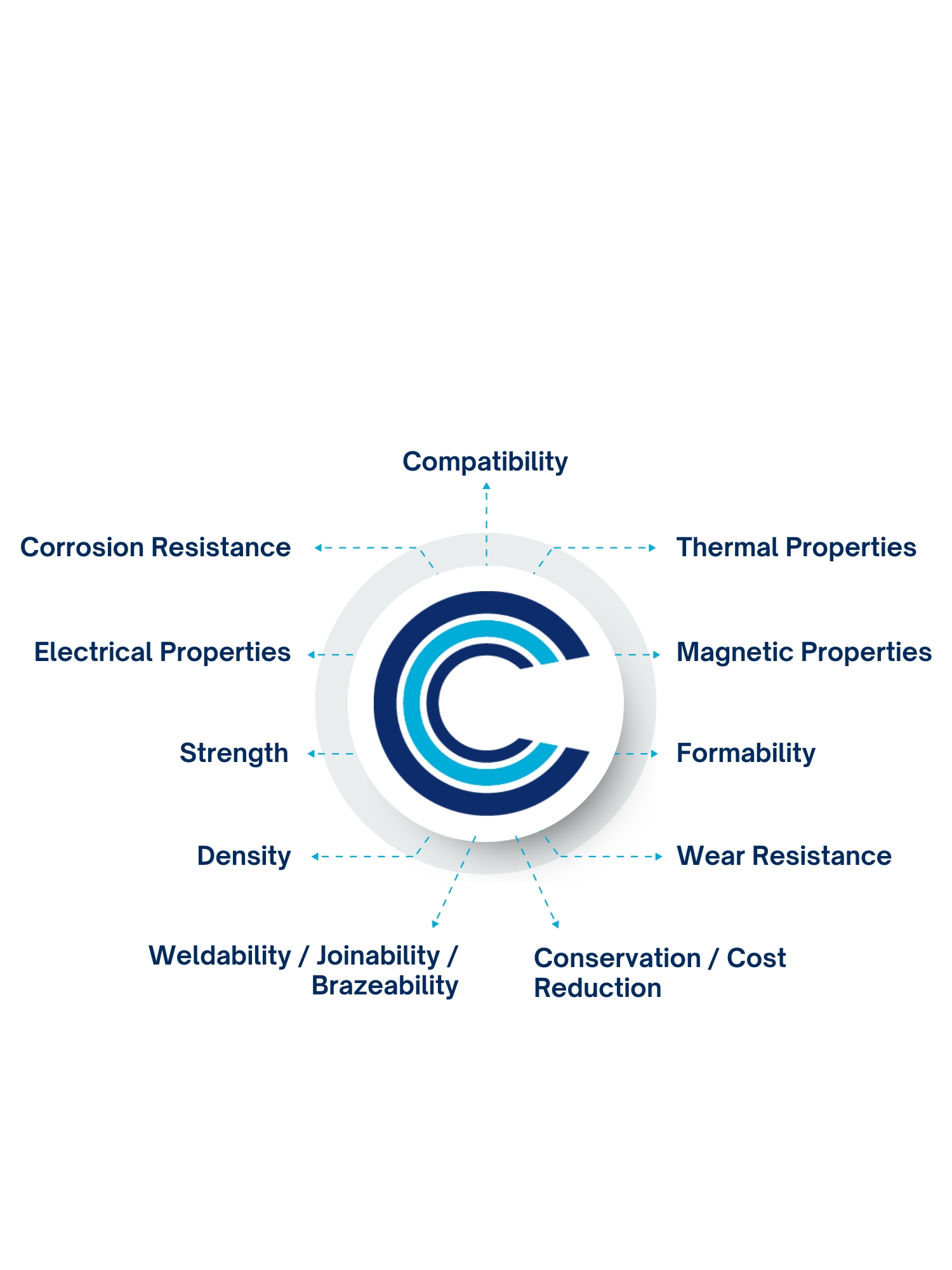

Clad metals offer the opportunity to combine desirable properties and/or characteristics of individual metals and alloys into a material “system” that provides improved characteristics over the individual metals:

|

|

Glossary

Many of the industry terms we use have specific definitions. We compiled this glossary to help.

Age Hardening

(Precipitation Hardening) A process of increasing the hardness and strength by the precipitation of particles of a phase from a supersaturated solid solution alloy. The hardening cycle usually consists of heating or annealing at a temperature sufficiently high to maintain solid solution, rapid cooling, or quenching to retain the supersaturated solid solution anneal to effect the precipitation.

Annealing

A process involving heating and cooling designed to effect: 1) softening of a cold-worked structure by recrystallizing or grain growth or both; 2) softening of an age-hardening alloy or causing a nearly complete precipitation of the second phase in relatively coarse form; 3) softening of certain age-hardenable alloys by dissolving the second phase and cooling rapidly enough to obtain a supersaturated solution; 4) relief of residual stress.

Burr

Is the thin ridge of roughness, left by a cutting operation such as slitting, shearing, blanking or sawing.

Camber

(Edgewise Curvation) The lateral departure of the edge from a straight line, which may be unidirectional or reversing; in the latter case, sometimes called snaking.