Demand for artificial intelligence is raising the bar in the semiconductor industry. The AI market in the United States is forecast to reach $299.64 billion by 2026 – it currently stands at about $196 billion – and will expand at a compound annual growth rate of 38.1% between 2022 and 2030. Chips to fuel that growth are highly coveted.

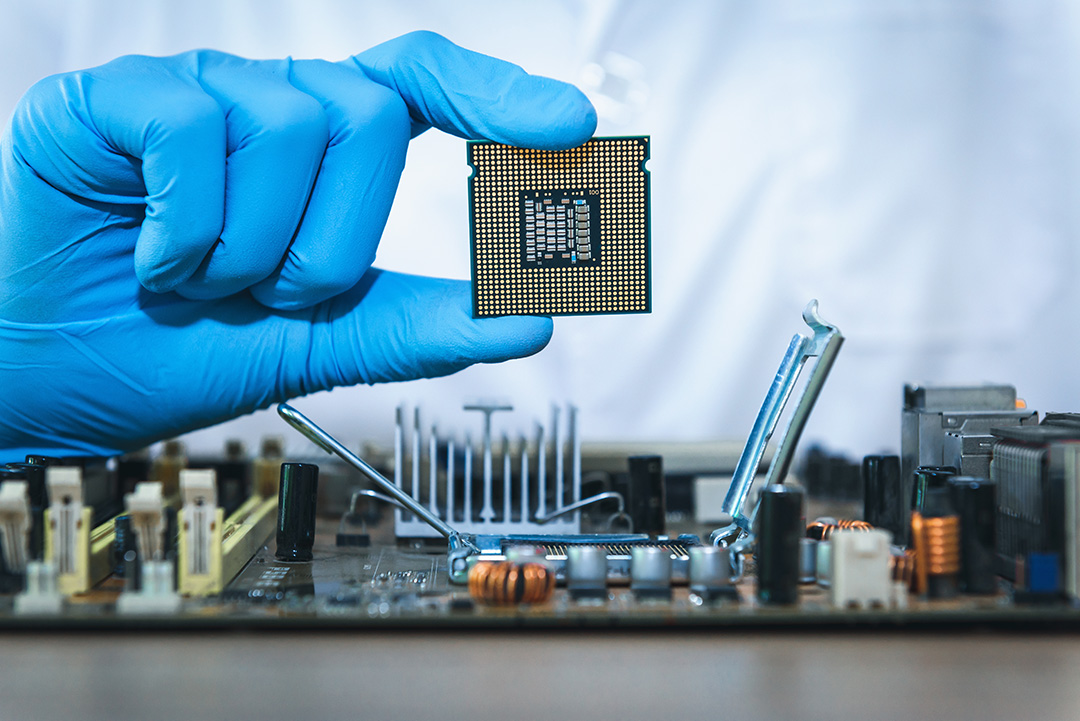

AI chips are different from traditional semiconductors because they are designed to handle large amounts of data for training and inference in AI applications. They are also designed to work with neural networks, which are a key component of many AI applications. A neural network is a machine learning algorithm that mimics the human brain’s structure and function to help computers solve complex problems.

They also often incorporate specialized hardware that helps speed up the training and inference process and are often designed to be power efficient. Many AI applications are deployed on mobile devices or other devices with limited power budgets.

Clad Metal Specialties process Nickel, Nickel-based alloys, Copper, and precious metals, such as silver, gold, palladium and platinum as base or clad products, which are critical components in the support of AI Chip Manufacturing.

The alloys are not only ideal for the AI chip industry, but essential. Without semiconductors used for AI chips (Silver, Nickel, etc.), they wouldn’t be able to be produced or improve chip performance in any way. They offer high-temperature resistance, thermal conductivity, high strength, superior electrical conductivity, corrosion resistance and wear resistance.

The thermal performance of nickel-based alloys is especially critical. The alloys maintain stable performance in high-temperature environments while transferring the heat generated by chips to larger heat dissipation areas. Through synergistic action with cooling structures, the nickel-based alloys assist in the efficient dissipation of heat. The process ensures the reliability of AI chips during high-load operations.

Nickels are used frequently in an assortment of semiconductor chips. Their ease of availability and lower cost are key considerations in addition to their performance in high-temperature applications. Also, nickel-based alloys offer advantages in the encapsulation and interconnection aspects of AI chips. Encapsulations are the packing of data and functions into a single component. Interconnection is critical for AI chips, as it connects two or more circuit elements electrically.

Valuable and precious metals are found in all sorts of computer components. Palladium is used in hard drives and circuit board components. Copper is used in computer chips, printed circuit boards, wiring and cables and CPU heat sinks. Gold is even found in connectors, printed circuit boards and computer chips. Silver, platinum, cobalt, aluminum and zinc are also frequently used.

Clad Metal Specialties’ capabilities are second to none when it comes to critical thickness, layer, and width tolerances as well as critical surface criteria/requirements. Clad Metal Specialties processes raw materials that play a critical part in the development of semiconductors to produce AI chips.

Semiconductor and AI chip manufacturing is expanding rapidly in the United States. The CHIPS Act in 2022 approved $52.7 billion in federal subsidies to support new semiconductor fabrication plants and other markets are also emerging for clad metals. CMS’ ability to offer different base and precious metal combinations is important for a variety of end-users, particularly those in the manufacturing of semiconductors and AI chips.

Clad Metal Specialties: Your Partner in Metal Selection

At Clad Metal Specialties, we provide more than just materials – we offer solutions. Our team, equipped with extensive industry knowledge, assists in offering the perfect metal combination for your projects, whether it involves inlay or overlay clads. Trust us to guide you through the complexities of metal selection, ensuring the success of your projects.

Explore our full range of services and how we can contribute to your next project at Clad Metal Specialties.